Packages

Industry and Production:

The automatic doors production line consists of electronic cutting machines, laser cutters, bending and shaping machines, high-quality presses and molds, electronic welding robots, sorters, programmed lathes, modern plastic injection machines, an automatic thermal spraying line, and assembly lines. All sensitive parts tested by using 3D accuracy devices, and all products undergo noise tests in insulated room.

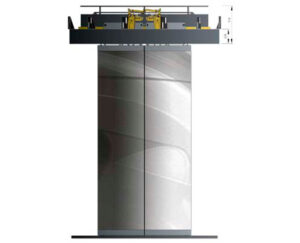

Automatic doors:

- Interior and exterior central and telescopic doors.

- Slim doors with three, four, or more panels.

- Door heights from 1200mm up to 2400mm or as request.

- Door widths from 600mm up to 3200mm or more.

- Stainless steel, electrostatic painted, and tempered glass panels.

- Rollers made of polyurethane to reduce noise and vibration.

- Secure mechanical locking system.

- Fire-resistant doors of type E120, EW60.

- High quality drive motor designed for elevator doors.

- Motor is developed to increase torque, speed, and stability.

- Programable speed curves and times for all stages.

- Internal protection circuits and fault analysis.

Manual doors:

- Opening range up to 2200mm for single and dual panels.

- The thickness of panel 1.5mm, and 2mm for frame.

- Opens up to 180 degrees according to the hinges type.

- Available in different models, colors and plating materilies.

Folding Doors:

- Available in two types of mechanisms.

- Stainless steel panels with aluminum hinges.

- Advanced electronic card for motor speed control with encoder.

- Lifetime warranty and available replacement parts.

Guillotine Door:

- Suitable for service elevators.

- Equipped with safety circuits and both electric and mechanical locks.

- Customizable dimensions design option available.

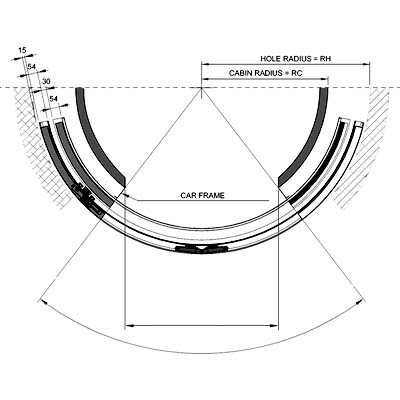

Circular doors:

- A new high-performance product designed to fit circular cabins.

- Available in various diameters and openings according to the request.